High Pressure

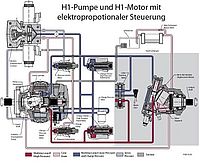

Series H1 Axial Piston Variable Displacement Motors

The series includes axial piston variable displacement pumps for closed circuits, axial piston fixed displacement motors, axial piston variable displacement motors, PLUS+1 compatible control software and hardware.

Die H1-Serie umfasst ca. 30 Leistungsstufen und/oder Konfigurationen.

Quality and reliability as a design maxim

- Uniform design concept

- Lower number of parts

- One-piece turntable

- Small number of control variants

- Lower number of parts for EDC (Electronic Displacement Control)

Benefits of integration and installation

- Optimized motor length

- Only one clean side

- Better ratio of peak power to installation size

- Integrated control function

- Standardized connection interface

Greater range of functions with PLUS 1

Optimized for electrical controls

- One electric delivery volume adjustment for all pump models

- Integrated electronic automotive control

- First-class EDC and PLUS 1 compatibility

- SIL 2, electronic automotive control (AC)

- 4 electrical control options (EDC, NFPE, electronic AC or FNR)

Extended functionality

- Integrated automotive pump and engine control functions

- Overriding the adjustment

- Integrated sensors optional (pressure, angle, speed)

- Electronically operated pressure limiter optional

- PLUS 1 compatible

More overall efficiency

- Optimized filling pump

- Minimal control losses

- Better equipment

- Lower control pressure

Series 51 and 51-1 Axial Piston Variable Displacement Motors

Variable displacement motors of the 51 and 51-1 series are bent axis motors with spherical pistons.The motors are used in combination with other products predominantly in closed circuits for the transmission of and control of hydraulic power. The motors of the 51 and 51-1 series are characterized by the very large displacement range Vg max. / Vg min. = 5 and very high output speeds. SAE flange motors, plug-in motors and DIN flange motors are available. A complete programme of adjustments and controls fulfils the requirements of a wide range of applications.The motors start normally with maximum displacement volume.

Thereby a maximum starting torque for a high acceleration is made possible. The displacement can be supplied with an internal setting pressure and be overlaid by constant pressure regulation (D min. -> D max.), which works not only in motorized mode, but also in generator mode. With a direction-dependent cut off, the constant pressure regulator overlay can be made ineffective in the generator mode of the motor (pump mode). The constant pressure regulator overlay has a low pressure increase (short ramp) and so enables the optimum use of the power over the complete control range of the motor.Motors with only constant pressure control (without cut off) are also available.

• the most technically advanced hydraulic units in the industry

• SAE flange motors, plug-in motors and DIN flange motors

• plug-in motors for direct fitting in compact planetary gearboxes

• large displacement range (5:1)

• complete Adjustment and control programme

• tried and tested reliability and performance

• optimum application range through standardized connections and modular

design

• light and compact

Series 90 Axial Piston Fixed Displacement Motors

The pumps and the motors of the 90 series can be used in hydraulic systems together or in combination with other products. They are intended for use in closed circuit applications. Variable displacement pumps of the 90 series are compact units with high power density. All models work on the parallel axial piston principle together with a variable swash plate with which the displacement of the pump is regulated.

Through the reversing of the angle of the swash plate the oil flow of the pump is reversed and, as a consequence, the direction of rotation of the motor. The pumps of the 90 series are equipped with an integral charging pump which serves to refill the system and to cool the oil flow, in addition it makes available the control oil. They also include a number of drive shafts for the mounting of additional hydraulic pumps for use in complementary hydraulic systems. For the adaption to the particular control system there are several adjustments available (mechanical, hydraulic, and electrical).

The motors of the 90 series also work on the parallel axial piston principle together with a fixed or variable swash plate. The inlet and outlet take place bidirectionally through one of the connections. Alternatively, circuit flushing is offered which alongside the cleaning of the oil in the work circuit also offers a cooling function.

• series 90 – today's advanced technology

• variable displacement pumps in seven sizes

• fixed displacement motors in five sizes

• variable displacement motors

• SAE and plug-in mounting configurations

• efficient axial piston design

• tried and tested reliability and performance

• light and compact

• sales and service worldwide